Super Purchasing for Fiberglass Insect Screen Mesh - Fiberglass Grinding Wheel Mesh with High Quality and Best Service – Ruifiber

Super Purchasing for Fiberglass Insect Screen Mesh - Fiberglass Grinding Wheel Mesh with High Quality and Best Service – Ruifiber Detail:

Fiberglass Grinding Wheel Mesh with High Quality and Best Service

● High Strength, Low Extensibility

● Coating with Resin Easily, Flat Surface

● High Temperature Resistant

Improving of Weaving Technique

Knitting with untwisted yarns: reduce the damage to the yarn during the weaving process, thereby better strengthening the glass fiber disc; theoretically, the untwisted yarn will be a finer combined yarn, which can reduce the glass fiber disc The thickness (according to data analysis) is conducive to thin or ultra-thin grinding wheels.

New weaving process: reduce the damage of the wrapping yarn during the assembly process, make the tensile strength in the weft direction uniform, and have a better strengthening effect on the glass fiber disc. In addition, the new weaving technology can help reduce the thickness of the product.

Fiberglass Grinding Wheel Mesh Data Sheet

| ITEM | WEIGHT(g/m2) | DENSITY COUNT(25mm) | TENSILE STRENGTH(N/50mm) | WOVEN STRUCTURE | ||

| WARP | WEFT | WARP | WEFT | |||

| DL5X5-190 | 190±5% | 5 | 5 | ≥1500 | ≥1500 | leno |

| DL5X5-240 | 240±5% | 5 | 5 | ≥1700 | ≥1800 | leno |

| DL5X5-260 | 260±5% | 5 | 5 | ≥2200 | ≥2200 | leno |

| DL5X5-320 | 320±5% | 5 | 5 | ≥2600 | ≥2600 | leno |

| DL6X6-100 | 100±5% | 6 | 6 | ≥800 | ≥800 | leno |

| DL6X6-190 | 190±5% | 6 | 6 | ≥1550 | ≥1550 | leno |

| DL8X8-125 | 125±5% | 8 | 8 | ≥1000 | ≥1000 | leno |

| DL8X8-170 | 170±5% | 8 | 8 | ≥1350 | ≥1350 | leno |

| DL8X8-260 | 260±5% | 8 | 8 | ≥2050 | ≥2050 | leno |

| DL8X8-320 | 320±5% | 8 | 8 | ≥2550 | ≥2550 | leno |

| DL10X10-100 | 100±5% | 10 | 10 | ≥800 | ≥800 | leno |

The regular supply of fiberglass grinding wheel mesh is DL5x5-240, DL5x5-320, DL6x6-190, DL8x8-170, DL10x10-90, etc.

With high strength and Low Extensibility, it can be used for cutting grinding wheel discs.

Comparison between C-glass & E-glass

Reinforcement for Fiberglass Grinding Wheel Mesh

The fabric is made of glass fiber yarn treated with silane coupling agent. There are two types of structures, plain weave and leno. It has many unique characteristics such as good bonding performance with resin, high strength, smooth fabric surface, low elongation, etc. It is an ideal base material for grinding wheel reinforced FRP discs.

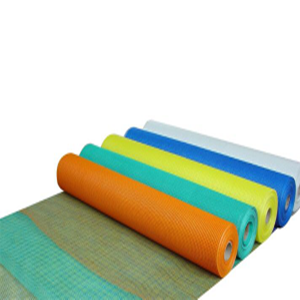

Product detail pictures:

Related Product Guide:

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of Super Purchasing for Fiberglass Insect Screen Mesh - Fiberglass Grinding Wheel Mesh with High Quality and Best Service – Ruifiber, The product will supply to all over the world, such as: Canberra, Madagascar, Tunisia, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.