Special Design for Fiberglass Insulated Copper Wire - Fiberglass Grinding Wheel Mesh with High Strength and low elongation – Ruifiber

Special Design for Fiberglass Insulated Copper Wire - Fiberglass Grinding Wheel Mesh with High Strength and low elongation – Ruifiber Detail:

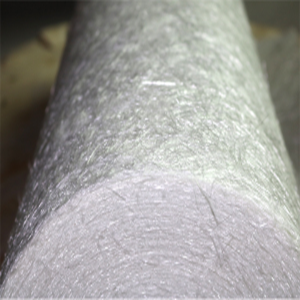

Fiberglass Grinding Wheel Brief Introduction

High tensile strength, allowing for use in hand lay-up process to produce large-area parts,

no airborne fiber when operating, good wet-through and fast wet-out in resins, rapid air

lease, high mechanical strength, superior acid corrosion resistance

Weaving Process

Weaving fabrics are made on looms with warp or weft reinforcement threads interlaced with each other in varying configurations to give different fabric styles.

Fiberglass Grinding Wheel Mesh Data Sheet

| ITEM | WEIGHT(g/m2) | DENSITY COUNT(25mm) | TENSILE STRENGTH(N/50mm) | WOVEN STRUCTURE | ||

| WARP | WEFT | WARP | WEFT | |||

| DL5X5-190 | 190±5% | 5 | 5 | ≥1500 | ≥1500 | leno |

| DL5X5-240 | 240±5% | 5 | 5 | ≥1700 | ≥1800 | leno |

| DL5X5-260 | 260±5% | 5 | 5 | ≥2200 | ≥2200 | leno |

| DL5X5-320 | 320±5% | 5 | 5 | ≥2600 | ≥2600 | leno |

| DL6X6-100 | 100±5% | 6 | 6 | ≥800 | ≥800 | leno |

| DL6X6-190 | 190±5% | 6 | 6 | ≥1550 | ≥1550 | leno |

| DL8X8-125 | 125±5% | 8 | 8 | ≥1000 | ≥1000 | leno |

| DL8X8-170 | 170±5% | 8 | 8 | ≥1350 | ≥1350 | leno |

| DL8X8-260 | 260±5% | 8 | 8 | ≥2050 | ≥2050 | leno |

| DL8X8-320 | 320±5% | 8 | 8 | ≥2550 | ≥2550 | leno |

| DL10X10-100 | 100±5% | 10 | 10 | ≥800 | ≥800 | leno |

Rapid air lease reducing rolling out times, low resin consumption.

Features

Weaving Process

Woven fabrics are made on looms with warp or weft reinforcement threads interlaced with each other in varying configurations to give different fabric styles.

Product detail pictures:

Related Product Guide:

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for Special Design for Fiberglass Insulated Copper Wire - Fiberglass Grinding Wheel Mesh with High Strength and low elongation – Ruifiber, The product will supply to all over the world, such as: Slovakia, Gambia, Kuwait, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.