Current market conditions are driving up the cost of many raw materials. So, if you’re a buyer or purchasing manager, you may have recently been inundated with price increases across multiple areas of your business. Regrettably, packaging prices are being affected too.

There are a lot of different factors contributing to the increase in raw material costs. Here’s a short summary explaining them for you…

Pandemic life changing the way we shop

With the closure of physical retail for much of 2020 and into 2021, consumers have turned to online shopping. Last year, internet retail exploded with 5 years growth in an instance. The upturn in sales means that the amount of corrugate needed to produce packaging was equivalent to the total output of 2 paper mills.

As a society we’ve chosen to shop online for the essentials as well as comforting ourselves with treats, takeaways and DIY meal kits to add some entertainment into our lives. All of this has put a strain on the amount of packaging businesses need to get products safely to our doors.

You might have even seen the cardboard shortage references on the news. Both the BBC and The Times have taken note and published pieces about the situation. To find out more you could also click here to read a statement from the confederation of paper industries (CPI). It gives explains the current position of the corrugated cardboard industry.

Deliveries to our homes don’t just rely on cardboard, and use protection like bubble wrap, air bags and tape or may use polythene mail bags instead. These are all polymer-based products and you’ll find this is the same material being used in bulk to produce essential PPE. This all puts more strain on raw materials.

Economic recovery in China

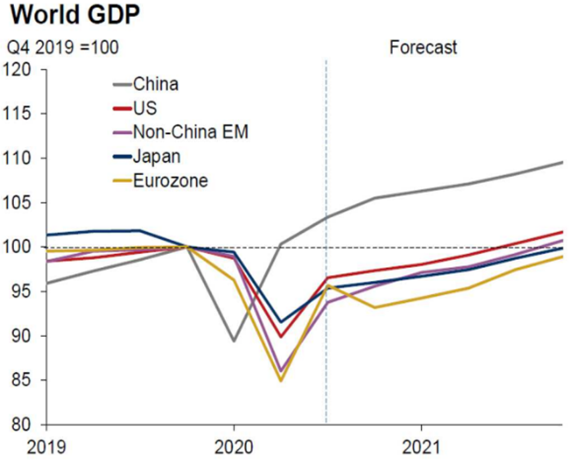

Whilst China might seem far away, it’s economic activities have an impact globally, even here in the UK.

Industrial production in China was up 6.9% YOY in October 2020. Essentially, this is because their economic recovery is ahead of the recovery in Europe. In turn, China has a greater demand for raw materials for manufacturing which is straining the already stretched worldwide supply chain.

Stockpiling and new regulations resulting from Brexit

Brexit will have a lasting impact on the UK for years to come. Uncertainty around the Brexit deal and fears of disruption means many companies stockpiled materials. Packaging included! The aim of this was to soften the impact of Brexit legislation introduced on 1st January. This perpetuated demand during a period in which it is already seasonally high, compounding supply issues and driving up prices.

Changes in legislation around UK to EU shipments using wooden packaging have also driven demand for heat-treated materials like pallets and crate boxes. Yet another strain on the supply and cost of raw materials.

Timber shortages impacting the supply chain

Adding to the already challenging situation, softwood materials are increasingly hard to come by. This is being exacerbated by bad weather, infestation or licensing issues depending on forest location.

The boom in home improvement and DIY means the construction industry is growing and there isn’t enough capacity in kiln processing to heat treat all of the timber required to meet our needs.

The shortage of shipping containers

The combination of the pandemic and Brexit had let to a significant shortage in shipping containers. Why? Well, the short answer is there are SO many being used. Many containers are storing things like critical PPE for the NHS and for other healthcare services around the world. Instantly, there are thousands of shipping containers out of use.

The result? Dramatically higher freight costs, adding to the woes in the raw material supply chain.

Post time: Jun-16-2021