Manufacturer of Epoxy Filler For Fiberglass - Fiberglass Grinding Wheel Mesh-DL5X5-240-Disc Reinforced Material – Ruifiber

Manufacturer of Epoxy Filler For Fiberglass - Fiberglass Grinding Wheel Mesh-DL5X5-240-Disc Reinforced Material – Ruifiber Detail:

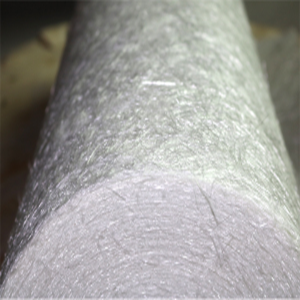

Fiberglass Grinding Wheel Brief Introduction

● High Strength, Low Extensibility

● Coating with Resin Easily, Flat Surface

● High Temperature Resistant

Improving of Weaving Technique

Weaving from yarns without twist: Reduce the damage on yarns during textile process so that to achieve better reinforcement for glass fiber discs; Theoretically speaking, yarns without twist will be thinner coalition yarns, could reduce the thickness of glass fiber discs(under data analysis), beneficial to thin or ultrathin grinding wheels.

New weaving technique: reduce the damage on wrap yarns during coalition process, uniform the tensile strength from wrap and fill direction, make better reinforcement for glass fiber discs. Also the new weaving technique can help reduce the thickness of products.

Fiberglass Grinding Wheel Mesh Data Sheet

| ITEM | WEIGHT(g/m2) | DENSITY COUNT(25mm) | TENSILE STRENGTH(N/50mm) | WOVEN STRUCTURE | ||

| WARP | WEFT | WARP | WEFT | |||

| DL5X5-240 | 240±5% | 5 | 5 | ≥1700 | ≥1800 | leno |

| RESULT | 1780 | 1988 | ||||

The regular supply of fiberglass grinding wheel mesh is DL5x5-240, DL5x5-320, DL6x6-190, DL8x8-170, DL10x10-90, etc.

With high strength and Low Extensibility, it can be used for cutting grinding wheel discs.

Comparison between C-glass & E-glass

Reinforcement for Fiberglass Grinding Wheel Mesh

Fiberglass grinding wheel mesh is usually used as a reinforcing material in composite materials, electrical insulation materials and thermal insulation materials, circuit boards and other fields of the national economy.

It is widely used in wall reinforcement, exterior wall insulation, roof waterproofing, etc., and can also be used to enhance wall materials such as cement, plastic, asphalt, marble, mosaic, etc. It is an ideal engineering material for the construction industry.

With features of high tensile strength and deflection resistance, good combination with abrasives, excellent heat resistance when cutting, it is the best base material for making different retinoid grinding wheels.

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Manufacturer of Epoxy Filler For Fiberglass - Fiberglass Grinding Wheel Mesh-DL5X5-240-Disc Reinforced Material – Ruifiber, The product will supply to all over the world, such as: Nairobi, Costa Rica, Italy, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!