Manufacturer for Industrial Fabric Composite Reinforcement - Fiberglass grinding wheel mesh-make your discs stronger – Ruifiber

Manufacturer for Industrial Fabric Composite Reinforcement - Fiberglass grinding wheel mesh-make your discs stronger – Ruifiber Detail:

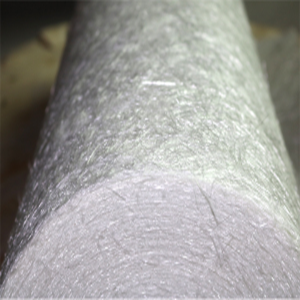

Fiberglass Grinding Wheel Brief Introduction

● High Strength, Low Extensibility

● Coating with Resin Easily, Flat Surface

● High Temperature Resistant

Improving of Weaving Technique

Weaving from yarns without twist: Reduce the damage on yarns during textile process so that to achieve better reinforcement for glass fiber discs; Theoretically speaking, yarns without twist will be thinner coalition yarns, could reduce the thickness of glass fiber discs(under data analysis), beneficial to thin or ultrathin grinding wheels.

New weaving technique: reduce the damage on wrap yarns during coalition process, uniform the tensile strength from wrap and fill direction, make better reinforcement for glass fiber discs. Also the new weaving technique can help reduce the thickness of products.

Fiberglass Grinding Wheel Mesh Data Sheet

| ITEM | WEIGHT(g/m2) | DENSITY COUNT(25mm) | TENSILE STRENGTH(N/50mm) | WOVEN STRUCTURE | ||

| WARP | WEFT | WARP | WEFT | |||

| DL5X5-190 | 190±5% | 5 | 5 | ≥1500 | ≥1500 | leno |

| DL5X5-240 | 240±5% | 5 | 5 | ≥1700 | ≥1800 | leno |

| DL5X5-260 | 260±5% | 5 | 5 | ≥2200 | ≥2200 | leno |

| DL5X5-320 | 320±5% | 5 | 5 | ≥2600 | ≥2600 | leno |

| DL6X6-100 | 100±5% | 6 | 6 | ≥800 | ≥800 | leno |

| DL6X6-190 | 190±5% | 6 | 6 | ≥1550 | ≥1550 | leno |

| DL8X8-125 | 125±5% | 8 | 8 | ≥1000 | ≥1000 | leno |

| DL8X8-170 | 170±5% | 8 | 8 | ≥1350 | ≥1350 | leno |

| DL8X8-260 | 260±5% | 8 | 8 | ≥2050 | ≥2050 | leno |

| DL8X8-320 | 320±5% | 8 | 8 | ≥2550 | ≥2550 | leno |

| DL10X10-100 | 100±5% | 10 | 10 | ≥800 | ≥800 | leno |

The regular supply of fiberglass grinding wheel mesh is as below showing:

Fiberglass Woven Fabrics-Leno DL5x5-190-113 5×5/inch,190g/m2,113cm

Fiberglass Woven Fabrics-Leno DL5x5-190-116 5×5/inch,190g/m2,116cm

Fiberglass Woven Fabrics-Leno DL5x5-240-100 5×5/inch,240g/m2,100cm

Fiberglass Woven Fabrics-Leno DL5x5-260-107 5×5/inch,260g/m2,107cm

Fiberglass Woven Fabrics-Leno DL5x5-320-107 5×5/inch,320g/m2,107cm

Fiberglass Woven Fabrics-Leno DL6x6-190-100 6×6/inch,190g/m2,100cm

Fiberglass Woven Fabrics-Leno DL6x6-190-107 6×6/inch,190g/m2,107cm

Fiberglass Woven Fabrics-Leno DL6x6-190-113 6×6/inch,190g/m2,113cm

Fiberglass Woven Fabrics-Leno DL10x10-90-100 10×10/inch,90g/m2,100cm

Fiberglass Woven Fabrics-Leno DL10x10-90-115 10×10/inch,90g/m2,115cm

With high strength and Low Extensibility, it can be used for cutting grinding wheel discs.

Comparison between C-glass & E-glass

Reinforcement for Fiberglass Grinding Wheel Mesh

Fiberglass grinding wheel mesh is usually used as a reinforcing material in composite materials, electrical insulation materials and thermal insulation materials, circuit boards and other fields of the national economy.

It is widely used in wall reinforcement, exterior wall insulation, roof waterproofing, etc., and can also be used to enhance wall materials such as cement, plastic, asphalt, marble, mosaic, etc. It is an ideal engineering material for the construction industry.

With features of high tensile strength and deflection resistance, good combination with abrasives, excellent heat resistance when cutting, it is the best base material for making different retinoid grinding wheels.

PACKING AND DELIVERY

Honors

Company Profile

Ruifiber is a industry and trade integration business, major in fiberglass products

Ruifiber is always dedicated to produce consistent products in line with our customers’ requirements and we want to be acknowledged for reliability, flexibility, responsivenss,innovative products and services.

Product detail pictures:

Related Product Guide:

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for Manufacturer for Industrial Fabric Composite Reinforcement - Fiberglass grinding wheel mesh-make your discs stronger – Ruifiber, The product will supply to all over the world, such as: Japan, Poland, British, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.