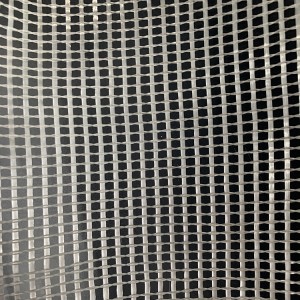

Fiberglass Grinding Wheel Mesh with High Strength and low elongation

Fiberglass Grinding Wheel Brief Introduction

High tensile strength, allowing for use in hand lay-up process to produce large-area parts,

no airborne fiber when operating, good wet-through and fast wet-out in resins, rapid air

lease, high mechanical strength, superior acid corrosion resistance

Weaving Process

Weaving fabrics are made on looms with warp or weft reinforcement threads interlaced with each other in varying configurations to give different fabric styles.

Fiberglass Grinding Wheel Mesh Data Sheet

| ITEM | WEIGHT(g/m2) | DENSITY COUNT(25mm) | TENSILE STRENGTH(N/50mm) | WOVEN STRUCTURE | ||

| WARP | WEFT | WARP | WEFT | |||

| DL5X5-190 | 190±5% | 5 | 5 | ≥1500 | ≥1500 | leno |

| DL5X5-240 | 240±5% | 5 | 5 | ≥1700 | ≥1800 | leno |

| DL5X5-260 | 260±5% | 5 | 5 | ≥2200 | ≥2200 | leno |

| DL5X5-320 | 320±5% | 5 | 5 | ≥2600 | ≥2600 | leno |

| DL6X6-100 | 100±5% | 6 | 6 | ≥800 | ≥800 | leno |

| DL6X6-190 | 190±5% | 6 | 6 | ≥1550 | ≥1550 | leno |

| DL8X8-125 | 125±5% | 8 | 8 | ≥1000 | ≥1000 | leno |

| DL8X8-170 | 170±5% | 8 | 8 | ≥1350 | ≥1350 | leno |

| DL8X8-260 | 260±5% | 8 | 8 | ≥2050 | ≥2050 | leno |

| DL8X8-320 | 320±5% | 8 | 8 | ≥2550 | ≥2550 | leno |

| DL10X10-100 | 100±5% | 10 | 10 | ≥800 | ≥800 | leno |

Rapid air lease reducing rolling out times, low resin consumption.

Features

Weaving Process

PACKING AND DELIVERY

Honors

Company Profile

Ruifiber is a industry and trade integration business,major in fiberglass products We have our own 4 factories,one of which produces our own fiberglass discs and fiberglass woven fabrics for grinding wheel,other 2 make laid scrim, which is a kind of reinforcement materilal,mainly used in pipeline prapping, aluminium foil composite,adhesive tape,paper bags with windows,PE film laminated,PVC/wooden flooring,carpets,automobile,lightweight construction,packaging,building,filter and medical field etc.Other one factory manufacture paper joint tape,corner tape,fiberglass adhesive tape, mesh cloth,wall patch etc.

The factories are seated in Jiangsu province and Shangdong province, respectively.Our company is located in Baoshan District,Shanghai,only

41.7km away from Shanghai Pu dong international airport and about 10km away from Shanghai train station.

Ruifiber is always dedicated to produce consistent products in line with our customers'requirements and we want to be acknowledged for reliability, flexibility,responsivenss,innovative products and services.