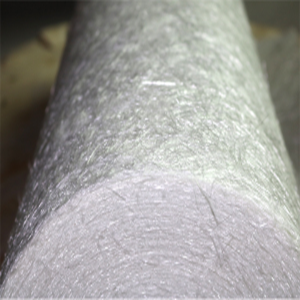

Fiberglass logric loven bakeng sa wheel of Shanghai Ruifiber

Kenyelletso ea grindisaning ea fiberglass grinding

● Pele: Matla a phahameng, a nang le ts'ebeletso e tlase

● Taba ea bobeli: koae ka habonolo, bokaholimo

● La boraro: mocheso o phahameng o hanyetsang

Ho ntlafatsoa hoaWea sebetsaTEchique

Moetso: Ho fokotsa li-sorns ntle le twist: fokotsa tšenyo ea li-charns nakong ea ho fumana ts'ebetso e ntle bakeng sa li-discs tsa grab; Ka nepo ho bua ka nepo, li-yarns ntle le twist e tla ba tse tšesaane tsa likopo tsa fiber tsa khalase (tlasa mabili a data a), a le molemo ho le mabili a mosesane kapa a ulfarathin.

Mokhoa o mocha oa ho roala: fokotsa tšenyo ea li-chalns nakong ea bompoli, e le matla a ho ts'oara le ho tlatsa litaelo tse betere bakeng sa li-disc. Ts'ebetso e ncha ea ho roala e ka thusa ho fokotsa botenya ba lihlahisoa.

FiberglassHo tsikitlanya menoLeqephe la lintlha

| Ntho | Boima (G / M2) | Palo ea Desity (25mm) | Matla a Tenstile (N / 50mm) | Sebopeho se lohiloeng | ||

| Warp | Weft | Warp | Weft | |||

| Dl5x5-190 | 190 ± 5% | 5 | 5 | ≥1500 | ≥1500 | Leno |

| DL5X5-240 | 240 ± 5% | 5 | 5 | ≥1700 | ≥1800 | Leno |

| Dl5x5-260 | 260 ± 5% | 5 | 5 | ≥2200 | ≥2200 | Leno |

| Dl5x5-320 | 320 ± 5% | 5 | 5 | ≥2600 | ≥2600 | Leno |

| Dl6x6-100 | 100 ± 5% | 6 | 6 | ≥800 | ≥800 | Leno |

| Dl6x6-190 | 190 ± 5% | 6 | 6 | ≥1550 | ≥1550 | Leno |

| Dl8x8-125 | 125 ± 5% | 8 | 8 | ≥1000 | ≥1000 | Leno |

| Dl8x8-170 | 170 ± 5% | 8 | 8 | ≥1350 | ≥1350 | Leno |

| DL8X8-260 | 260 ± 5% | 8 | 8 | ≥2050 | ≥2050 | Leno |

| Dl8x8-320 | 320 ± 5% | 8 | 8 | ≥2550 | ≥2550 | Leno |

| Dl10x10-100 | 100 ± 5% | 10 | 10 | ≥800 | ≥800 | Leno |

Boholo ba rona bo tloaelehileng ke Dl5x5-240, Dl5x5-320, Dl6x6-190, Dl8x8-17x10-90, jl10x10-90, jl10x10-90, jl10x10-90, jl10x10-90, jl10x10-90, jl10x10-90, jl10x10-90

Ka matla le ho hlaolela ho feteletseng, e ka sebelisoa bakeng sa ho seha mabitla a grandic.

Papiso lipakeng tsa khalase ea C-khalase

Matlafatso bakeng sa fiberglassHo tsikitlanya meno

Fiberglass grinding wheel Meshhangata e sebelisoa e le thepa ea ho tsitsipanya ka lisebelisoa tsa motlakase, lisebelisoa tsa motlakase tsa motlakase, lisebelisoa tsa theknoloji tsa motlakase, liboto tsa potoloho le libaka tse ling tsa moruo oa naha.

E sebelisoa haholo leboteng la lebota, lebota la kantle ho naha, marulelo, la polasetiki, la polasetiki, la polasetiki. Ke ntho e ntle ea boenjiniere indasteri.

Ka likarolo tsa matla a phahameng a matla a phahameng le ho qojoa ka matla, ho kopanya hantle ha u itšeha, ke thepa e ngata ea ho lisa.